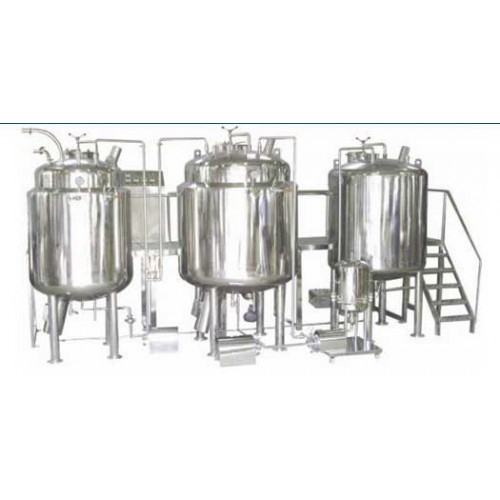

About Liquid - Oral Manufacturing Plant

Unlock the capabilities of the venerable LIQUID - ORAL MANUFACTURING PLANT, designed to provide enlightened manufacturing solutions for industries across the globe. With its computerized interface and valiant performance driven by electric automation, this robust machine ensures effortless production processes. Constructed with stainless steel and a sleek silver finish, it operates at voltages ranging from 220 to 440 volts. This admired industrial machine is automatic and exemplifies popular innovation, offering flexibility and efficiency to manufacturers, traders, and exporters alike.

Application Method and Surface Usability

The LIQUID - ORAL MANUFACTURING PLANT employs advanced applications, serving as a cornerstone for liquid oral production. Perfectly suited for a variety of surfaces within industrial environments, this specialized equipment ensures seamless operational functionality across its usage spectrum.

Domestic and International Market Accessibility

With robust transport services, the plant spans vast domestic and international markets. Its sustainable outlay and adept transportation solutions via FOB ports ensure timely and efficient delivery, catering to a global clientele with utmost precision.

FAQs of LIQUID - ORAL MANUFACTURING PLANT:

Q: How does the LIQUID - ORAL MANUFACTURING PLANT operate?

A: The plant operates automatically with a computerized system powered by electric drive type, ensuring seamless manufacturing processes.

Q: What benefits does the stainless steel construction offer?

A: The stainless steel construction provides durability, resistance to corrosion, and maintains a pristine silver finish.

Q: When is this plant most commonly used?

A: It is commonly used in industrial sectors requiring efficient production of liquid oral products.

Q: Where is this manufacturing plant primarily distributed?

A: It is primarily distributed across India and international markets, facilitated by exporter and supplier networks.

Q: What is the voltage range of the LIQUID - ORAL MANUFACTURING PLANT?

A: The plant operates within a voltage range of 220 to 440 volts, ensuring adaptability to various power setups.

Q: What processes does the plant streamline?

A: It streamlines the manufacturing of liquid oral products with computerized automation and electric efficiency.

Q: What is the benefit of using such advanced equipment?

A: The benefit includes automated production, increased efficiency, and reduced manual intervention, enhancing output quality and consistency.